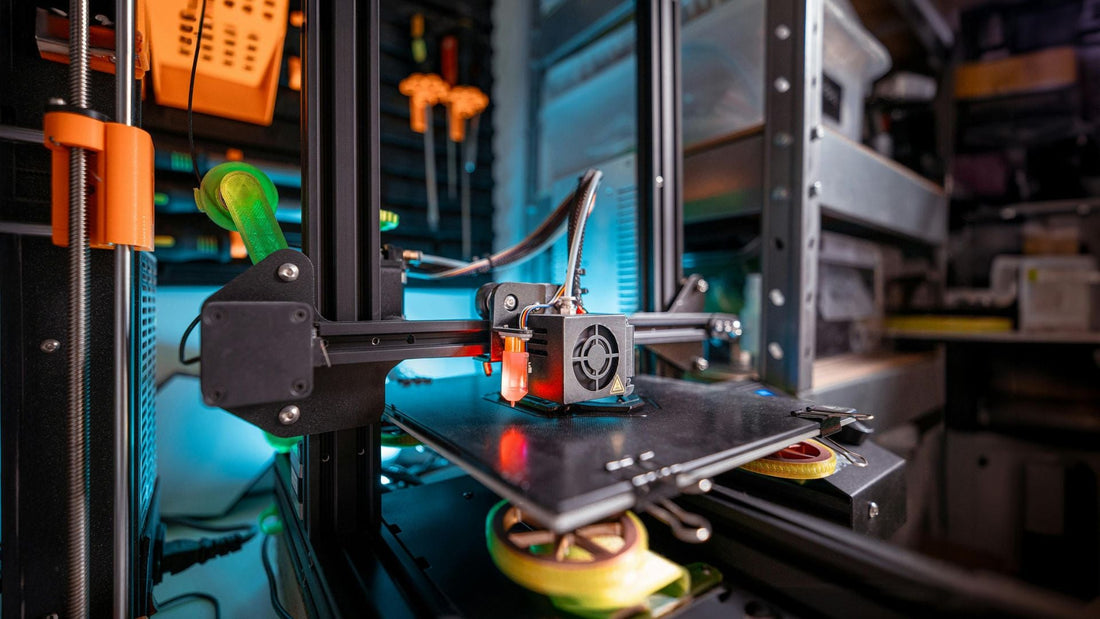

When it comes to manufacturing parts and products, choosing the right method can make all the difference in quality and performance. At ANW Machine Works, we specialize in injection molded parts, including the popular Evolution golf cart accessories and other golf cart parts. ABS injection molding stands out as a superior option compared to 3D printing. In this blog post, we’ll explore several reasons why ABS injection molding is the preferred choice for many applications.

Strength and Durability

One of the most compelling advantages of ABS injection molding is its strength and durability. Parts created through this process are made from a single solid piece of material, which results in a robust final product. In contrast, 3D-printed parts are built layer by layer, creating potential weak points that can compromise their integrity. This difference in manufacturing leads to injection-molded parts being more resilient and capable of withstanding greater stress and strain.

Precision and Consistency

Precision is crucial in manufacturing, and ABS injection molding excels in this area. The process allows for tighter tolerances and superior part quality due to carefully designed molds. As a result, dimensions are more consistent across large production runs, ensuring that each part fits perfectly with others. 3D printing can struggle with dimensional accuracy, especially when producing multiple items, leading to variability that may not meet stringent quality standards.

High-Volume Production

For businesses looking to scale production, ABS injection molding is the clear winner. This method is specifically designed for high-volume manufacturing, providing faster output with minimal variation. Unlike 3D printing, which can be time-consuming and inefficient for large quantities, injection molding allows for rapid replication of parts, making it an ideal choice for mass production environments.

Smooth Surface Finish

Aesthetics can matter just as much as functionality, and in this aspect, ABS injection molding offers a significant advantage. The process results in a smoother surface finish, free from visible layer lines often seen in 3D printed items. This not only enhances the visual appeal of the final products but also improves their performance, as a smoother finish can reduce friction and wear in mechanical applications.

Material Options

While 3D printing boasts a wide range of materials, ABS injection molding provides access to an even broader spectrum of plastic materials, each tailored specifically to the application. This flexibility allows manufacturers to select materials with properties like heat resistance, chemical resilience, and impact strength, ensuring the final product is perfectly suited for its intended use.

ABS injection molding proves to be a superior choice over 3D printing for many applications, especially when it comes to choosing Evolution golf cart accessories. If you’re looking for quality and reliable accessories for your customized golf carts, consider investing in ABS injection molded parts. Contact ANW Machine Works and explore our catalog today!